Monthly Archives: July 2013

27.05.2013 Haswell Colliery

Our third stop of the day was to the village of Haswell Plough to visit the site of Haswell Colliery (NZ 373422) which operated between 1833 and 1896. The colliery site was cleared some years ago but a substantial part of the pumping engine house remains and is still worth a visit.

Colliery Timeline:

1811 First sinking at Haswell proves coal exists underneath the magnesian limestone.

1831 Work begins on Engine Pit, but after digging through 54 ft of sand the pit is lost.

1833 The New Engine Pit is commenced at Haswell and is sunk down to the Hutton seam.

1834 After more than three years workmen employed in the sinking of Haswell colliery strike upon a fine seam of coal 504 feet below the surface

1835 – March 9th 200 workmen succeeded in winning the Hutton seam of coal, 5 feet 6 inches thick, at a depth of 930 feet from the surface.

1835 – July 2nd The first cargo of coals from Haswell colliery were shipped at Seaham. A public dinner was held in the afternoon, at the Lord Seaham Inn

1836 About eight miles of the eastern division of the Sunderland and Durham railway was opened. Several trains of wagons laden with coal traveled along a new line from Haswell colliery to Sunderland.

1844 The Haswell colliery mining disaster. 95 men and boys lost their lives.

1886 The Hutton seam is abandoned.

1895 Engine Pit closed.

1896 – Dec 31st Five Quarter, Main Coal, and Low Main seams are abandoned. The colliery is closed due to being unprofitable to work.

Interesting Fact:

Haswell Colliery can also lay claim to being the site where the first steel cable ever to be used down a mine shaft was deployed.

Historic Photos

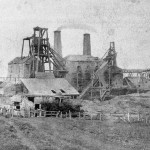

The following photograph was taken 20.05.1864.

The pumping engine house is to the left of the two chimneys.

Another from 1943.

A few more from around 1960 before landscaping.

The Site Today:

Even though most of the pumping engine house has been demolished and buried following the landscaping of the site the front Bob wall adjacent to the shaft is still very interesting to look at. It has largely been constructed of local limestone but the mounting block for the beam itself is made of imported sandstone which is harder and would take the weight and motion of the beam better.

Protected: 24/07/2013 Grinkle Mine

Protected: 20/07/2013 Grinkle Mine

Protected: 19/07/2013 North Loftus Mine Fanhouse

27.05.2013 Ryhope Engines Museum

The Ryhope Engines Museum is based at Ryhope Pumping Station which was built in 1868 to supply water to the Sunderland area. The station ceased operation in 1967 – after 100 years of continuous use.

Background

As the Industrial Revolution developed new challenges were thrown up. A rapidly growing population in the nineteenth century, much of which was concentrated in new mining villages throughout the Northumberland and Durham coalfield, together with the growth of new industries and expansion of older ones in towns like Sunderland (now a city), produced a rapidly increasing demand for water for domestic and industrial requirements.

Various sources were used to meet this demand. Rivers, natural springs, surface reservoirs and wells were used. In North East Durham, however, abundant supplies of good quality water were on the doorstep, or, more correctly, in the cellar, for it lay within the geological stratum known as magnesian limestone.

During the first half of the nineteenth century repeated cholera outbreaks, both nationally and locally led to a much greater concern for water supplies. The creation of the Sunderland and South Shields Water Company in 1852 was one local result of this.

The Construction

At the time the Company received the Royal Assent there were several pumping stations in districts around Sunderland but the urgency of water demands pressed heavily upon the Company. In 1864 four acres of land at Ryhope were acquired and in May of the following year Thomas Hawksley, in his position as Engineer to the Company, was asked to provide designs and specifications for the ‘new works’.

Construction of the engine house was not without its problems. The beam engines and their house form an integrated structure. Not only did the foundations have to serve as foundations for most of the engine components, as well as provide support for the well heads, but also the massive rocking beams had to be supported at some twenty-two feet above ground level. Therefore engine and engine house construction had to proceed together, but not in such a manner that they would interfere with the sinking of the wells.

The Exterior

Ground Floor

The First Floor

The Second Floor

Boiler Plant

Coal Store

The Blacksmiths

Videos

To Make this post even bulkier here is a load of video footage shot inside the museum largely showing the various parts of the engine at work.