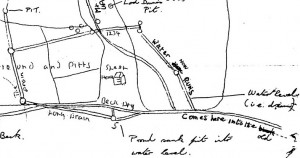

While most of the country was distracted with celebrating the Diamond Jubilee a small group from CHMS was investigating other minerals in the North Pennines. Simon, Gavin and John first congregated at Rookhope Arch where Neil soon joined us and we were introduced to John Crompton, former surveyor of various mines in the local area. John brought along a County Series 6 inch map of 1930 covering Rookhope district, and also a plan of the older workings of Grove Rake. After much debate and a few good stories John left with a few rock samples from Boulby. Eric and Dave then arrived and we returned to the village hall car park for a wander around Boltsburn Mine.

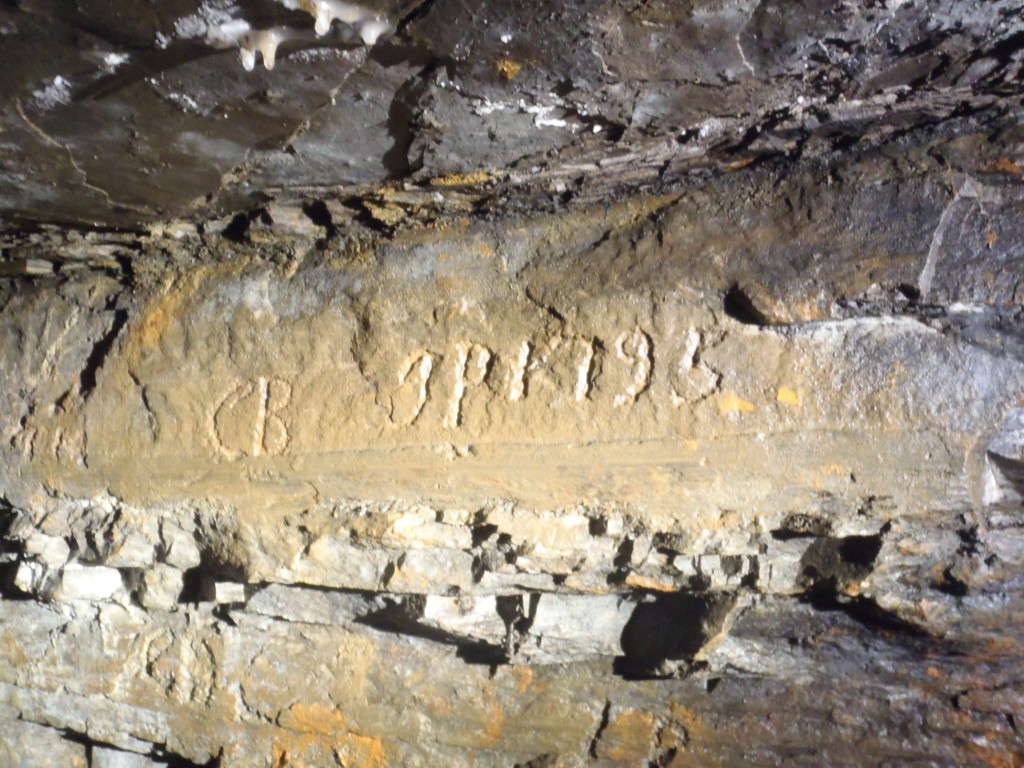

About a 100m to the west of the shaft is a level, West Level surprisingly, which is ankle deep wet and soon comes into an area of room-and-stall ironstone workings. The ironstone seems to have been quite soft and in a deposited state, not the stratified condition we are used to, and was worked by pick although a couple of drill marks were found. The main adit is stone lined and at a weak point they appear to have reinforced the roof with old wrought-iron rails held in place with more modern flat-bottomed ones. The main adit continues a short distance beyond the ironstone workings, again stone lined until a fall blocks further progress. The fall is dry but the level is wet and Neil noticed just in front of the fall wooden flooring with a substantial flow of water coming out of it, so if anyone visits watch out for this hazard. We inserted John’s walking stick into the hole, all 4 feet 7 inches of it, so depth is unknown.

Whilst everyone passed over a rail in the level, it was Simon who looked at it closely and it proved to be a length of plateway, the third different type of rail to be seen in this short level. Altogether a most interesting short excursion.

Back at Boltsburn Shaft we managed to pull ourselves away from gazing at the collection of pre-owned machinery, saucepans, stoves and about everything else, to look at the shaft top in close detail. The shaft is circular and stone lined and flooded almost to the top. Running north-south across the western side has been the pumping gear operated by a water-wheel. Within the shaft itself the top of an open vertical pipe is apparent with a steel rod rising out of it up to a coupling at the end of a steel quadrant perched on the north side of the shaft. This quadrant has a base length of about 12 feet with a central strut forming the triangle at about 6 feet. The north end of the quadrant has a square balance box in place. Dangling down from the top of the triangle is the drive rod, a wooden arm about 6 inches square, apparently driven from a waterwheel further north, and sawn through.

South of the vertical pipe is another one in the shaft with its rod projecting upwards but nothing else. In the south side of the shaft is another position for a quadrant similar to the one remaining but the quadrant itself is missing and the space is full of rubbish. Both positions appear to be modifications to the shaft top made of concrete and the use of a quadrant made up of riveted steel suggest a possible installation date of c.1900.

The survival of such a quadrant on a mining site in Britain may now be unique so a return visit for surveying is planned.

Unfortunately rain and the time drove us away for shelter and lunch and then we headed upvalley to Grove Rake. Immediately noticeable was the side wall of the secondary winding house which has collapsed but makes the machinery inside easier to photograph. After a mooch around we wandered up to the site of the drift at Fraser’s Grove for a bit of fossicking on the dumps of spoil. We also found a drill rod of good length.

Back at the main mine we looked closely at the remaining headgear which is equipped with a single man-riding cage and a counter-balance. There are four guide ropes for the cage, two for the balance, and another two between as rubbing strips. There is an inset at ground level where the cage now sits, blocking access into the shaft. Above is another inset then above that a boxed-in section with steel grooves inside where a skip could be angled away from the shaft and unloaded into a chute. At this level there is also a ‘cabin’ on the steps up the headgear perhaps for an operator of the chute mechanism. Within this enclosed part of the headgear the expanded mesh steel flooring is failing through rusting.

Above here is another inset, presumably for unloading the cage in the event of an overwind. At the top are the two pulley wheels, with one missing piece of flooring.

Next stop was Allenheads for a look into the re-opened Horse-level, and what a beauty that is! A cobbled floor, stone walls and arched roof, initially straight in then soon bends and descends to the left to end in a complete collapse. All the stonework was most impressive and the odd curtains of hanging roots added to the Gothic atmosphere! A word of warning – the steel gate is not yet fixed in place although it looks it so check first before it falls on any visitors.

We went up past the blacksmith’s shop and small exhibition centre (mineral specimen display cupboard collapses if touched) to look at a modern steel magazine then a much older stone one of unusual design, another structure worthy of surveying. We were following the vein(s) westward onto the open moor amongst shafts with gin circles and mounds and all manner of disturbed ground. All the shafts appear to have been capped, perhaps by British Steel some years ago. We also took great delight in looking at the remains of an old stone cottage in this very exposed location.

With the clock approaching 7 pm we departed Allenheads to reconvene at our regular port of call in Frosterley, the chippy. And so the weary travelers headed home to bed, to be tucked up dreaming of all the exciting places they had visited and things they had seen and envious of Simon and Dave who had reached the dizzy heights.